D3 Tool & Alloy Steel Round Bars Supplier, Stockist in Mumbai, India

IMI Alloys India LLP is the best company that produces and exports D3 Tools & Alloy Round Bars. We are manufacturing the best quality product using the best crude materials that offer high strengths abilities. We manufacture the forms, types, and custom made and defaults features specified round bars. Cold-work apparatus steels incorporating D2, D3, D4, D5, and D7 steels are high-carbon, high-chromium materials. From D3 steel, all bunch D steels have 1% Moment and are discuss solidified. Sort D3 steel is oil-quenched, even though little segments can be gas extinguished after treatment using a vacuum. The specifications of D3 Tools & Alloy Round Bars contain the shapes, sizes, designs, different properties, and more.

Table of Content

- What is D3 Tool & Alloy Steel Round Bars

- Standard Specification For D3 Tool & Alloy Steel Round Bars

- D3 Tool & Alloy Steel Round Bars Equivalent Grades

- Chemical Composition of D3 Tool & Alloy Steel Round Bar

- Mechanical Properties of D3 Tool & Alloy Steel Round Bars

- Searches Related to D3 Tool & Alloy Steel Round Bars

- D3 Tool & Alloy Steel Round Bars Applications

- Export Destinations for D3 Tool & Alloy Steel Round Bars

Alloy Steel D3 Round Bars Stockholder, IS-XT215Cr12 Round Bar, D3 Tool Steel, D3 Steel Round Bars, Alloy steel D3 bar, d3 tool steel alloy steel round bars stockist, Tool Steel D3 Round Bars, UNS T30403 Round Bars, D3 Tool & Alloy Steel Round Bars Suppliers, ASTM A681 D3 Tool & Alloy Steel Round Bars, D3 Tool Steel Round Bar, d3 tool steel alloy steel round bars Exporters, Alloy Steel D3 Round Bar, Tool Steel 1.2080 Round Bars Exporter, D3 Tool & Alloy Steel Round Bars Manufacturers, ASTM A681 D3 Tool Steel Round Bars Supplier in Mumbai, India.

The oil extinguished and tempered hardness of these bars is 28-34 HRc. We provide the D3 Tools & Alloy Round Bars, which are to be used by the applications demanding lengths as one-offs or different cut pieces, presenting a superiority exactness packed up bar to stretched resilience’s. IMI Alloys India LLP offers a diverse range of D3 tool steel and alloy steel products, including round bars, flat bars, and square bars. As a reliable stockist and supplier, we provide high-quality options for all your steel needs. Explore our collection through the following pages: Round Bars, D3 Tool & Alloy Steel Flat Bars, and D3 Tools & Alloy Steel Square Bars.

D2 vs D3 Tool Steel Round Bars?

High-carbon, high-chromium tool steels with the designations D2 and D3 are both renowned for their remarkable wear resistance and hardness. There are, however, some significant differences between the two. D2 has more wear resistance than D3 since it contains more carbon than D3. D3 is more corrosion-resistant than D2 because it contains more chromium. D2 normally has a Rockwell hardness of 60–62 HRC, whereas D3 typically has a hardness of 58–60 HRC. Because D2 has more carbon than D3, it is more brittle. Because D2 has a lower chromium content than D3, D3 is more resistant to deformation and chipping. In general, D2 is seen to be better suited for cutting tools, whereas D3 is thought to be better suited for punches, dies, and other applications requiring a high level of wear resistance and excellent surface quality. D2 often costs more and is more expensive to machine than D3. Generally speaking, D2 steel works well for cutting tools, while D3 steel is better for punches, dies, and other uses that call for a high level of wear resistance and a good surface polish.

How to maintain large d3 tool steel bar stock?

Large D3 tool steel bar stock needs to be kept in a cold, dry location to avoid rust and corrosion. The bars need to be shielded from humidity and moisture. Additionally, they must be maintained away from chemicals and heat sources. The bars must be kept pristine and clutter-free as well. It is important to frequently check the bars for wear or damage. Any broken bars need to be taken out of the stock and replaced. It’s crucial to maintain precise stock inventory records so that any missing or damaged bars may be found and replaced right away. In addition, appropriate lubrication, consistent cleaning, regular oiling, and corrosion prevention are required.

D3 Tool Steel Bar Stock, Carbon Steel D3 Hot Rolled Round Bars, Tool Steel T30403 Round Bar, Chrome Moly Steel D3 Round Bars Dealer, ASME SA681 D3 Hot Forged Round Bars, D3 Steel Properties, D3 Tool & Alloy Steel Industrial Round Bars, CrMo D3 Cold Drawn Round Bars, d3 tool steel alloy steel round bars Suppliers, D3 Tool & Alloy Steel Round Bars Exporters, D3 Tool & Alloy Steel Round Bars Stockist, d3 tool steel alloy steel round bars Manufacturers, Buy Comprehensive Variety of Quenched & Tempered D3 Alloy Steel Bar, JIS SKD1 Black Round Bars Stockist in India.

IMI Alloys India LLP, we are putting all our great efforts to bring out the best materials. D3 Tools & Alloy Round Bars are utilized in different manufacturing areas such as Highly stressed cutting, punching tools for thin sheets, Shear blades for cutting, Profile rolls, Stone processing tools, Knives for paper and plastics, Deep drawing, Pressure pads and many more. We deliver these D3 Tools & Alloy Round Bars following the safety measures. D3 is an oil hardening, high Carbon Chromium material type tool steel with very high wear resistance. It hardens with a very slight change in shapes, sizes. The alloy possesses very high compressive strength and is deep hardening. D3 is used in tooling applications requiring a high degree of accuracy in hardening, forming rolls, powder metal tooling and blanking and forming dies.

Specifications of D3 Tool & Alloy Steel Round Bars

- Standard : ASTM A681, ASME SA681

- Dimensions : EN, DIN, JIS, ASTM, BS, ASME, AISI

- Form : Round

- Diameter : 10 mm ~ 900 mm

- Size : 0.08 mm to 25.00 mm

- Diameter Range : 0.040 mm – 12 mm (0.0016” – 0.4724”)

- Application : Lathe Tools, Milling Cutter, Cutter Blades, Boring Tools, Twist drills, Milling Knives, Reamers, Taps, Metalcutting saws, Screw Cutting Tools, File Cutter’s Chissels, Drills, Hobs, Drill Bits, Tread cutting tools etc

Equivalent Grades of D3 Tool & Alloy Steel Round Bars

| Country | USA | German | Japan |

| Standard | ASTM A681 | DIN EN ISO 4957 | JIS G4404 |

| Grades | D3 | 1.2080/X210Cr12 | SKD1 |

Chemical Composition of D3 Tool & Alloy Steel Round Bar

| Element | C | Si | Mn | P | S | Cr | Ni | V | Cu | W |

| Content (%) | 2.00-2.35 | 0.60 | 0.60 | 0.03 | 0.30 | 11.00-13.50 | 0.30 | 1.00 | 0.02 | 1.00 |

Mechanical Properties of D3 Tool & Alloy Steel Round Bars

| Mechanical Properties | Metric | Imperial |

| Hardness, Knoop (converted from Rockwell C hardness) | 769 | 769 |

| Hardness, Rockwell C | 62 | 62 |

| Hardness, Vickers | 748 | 748 |

| Izod impact unnotched | 77.0 J | 56.8 ft-lb |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30457 ksi |

Thermal Properties of D3 Tool & Alloy Steel Round Bars

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Thermal expansion | 12 x 10-6/ºC | 20-100 | – |

Searches Related to D3 Tool & Alloy Steel Round Bars

cold work alloy steel d3 round bars suppliers in mumbai, tool steel d3 bars price per kg, d3 tool steel alloy steel round bars Stockist, tool steel round bar d3 price per kg in india, cr mo d3 round bars stockist in mumbai, tool steel uns t30403 rods, alloy steel d3 round bars manufacturers in mumbai, d3 tool & alloy steel round bar, tool steel d3 round bars / rods price list, dai steel d3 round bars manufacturers in india, high quality d3 cold work tool steel round bar, tool & alloy steel t30403 threaded bar, d3 chrome molybdenum steel round bars price, d3 steel round bars, chrome molybdenum steel d3 bright bars, high-chromium d3 round bars dealers, d3 alloy tool steel round bars manufacturers in delhi, a wide range of the best quality skd1 round bars stockist in india, skd1 round bars, d3 tool steel round bars, d3 tool steel & alloy steel round bar supplier, chrome molybdenum steel d3 round bars rate suppliers, high-carbon steel d3 round bars and rods, tool steel d3 round bar distributors, chrome moly d3 round bar, alloy steel d3 rods, d3 dai steel bars, d3 carbon steel rods price india, tool steel 1.2080 rod, d3 alloy steel round bars price per meter.

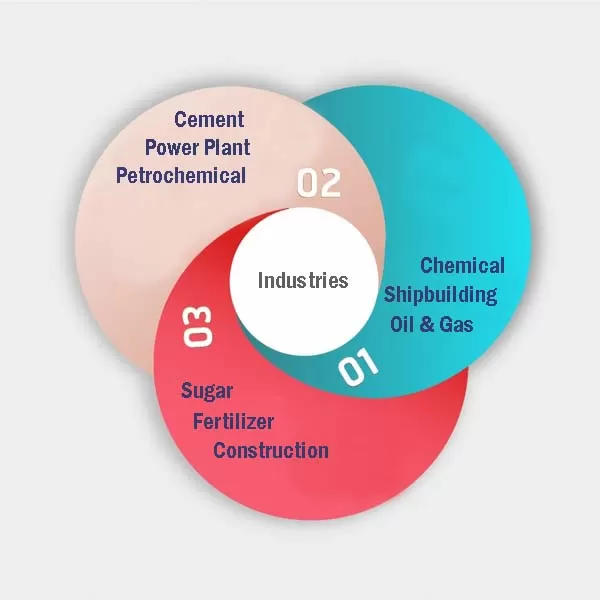

Applications For D3 Tool & Alloy Steel Round Bars

Generally, D3 tool steels are used for long run tooling applications, Some main applications for D3 Tool & Alloy Steel Round Bars materials are:

- Blanking Dies

- Forming Dies

- Coining Dies

- Slitting Cutters

- Heading Tools

- Long Punches

- Forming Rolls

- Edging Rolls

- Master Tools

- Beading Rolls

- Intricate Punches

- Extrusion Dies

- Drawing Dies

- Lamination Dies

- Thread Rolling Dies

- Burnishing Tools

Export Destinations for D3 Tool & Alloy Steel Round Bars

Countries

Cities

Products

- Round Bar

- High Speed Steel Round Bars

- Tool & Alloy Steel Round Bars

- D2 Tool & Alloy Steel Round Bars

- D3 Tool & Alloy Steel Round Bars

- S7 Tool & Alloy Steel Round Bars

- D6 Tool & Alloy Steel Round Bars

- S1 Tool & Alloy Steel Round Bars

- A2 Tool & Alloy Steel Round Bars

- H11 Tool & Alloy Steel Round Bars

- H13 Tool & Alloy Steel Round Bars

- EN24 Tool & Alloy Steel Round Bars

- EN 36C Tool & Alloy Steel Round Bars

- EN 52 Tool & Alloy Steel Round Bars

- H21 Tool & Alloy Steel Round Bars

- 21/4N Tool & Alloy Steel Round Bars

- OHNS Round Bars

- OHNS 01 Grade Round Bars

- Square Bar

- Flat Bar

- Powder Metallurgy

- Scrap

- Carbide Rods